You have the vision, we help you realize it

Much more than a plastic injection subcontractor, BUATHIER plays a strategic role as a FACILITATOR in the development of your products. Indeed, our atypical and heterogeneous team, accompanies you throughout the development process: from your idea to the finished product. Above all, our approach is centered on co-development, and is guided by curiosity, creativity and ingenious solutions. More over, our design office’s expertise extends to four key stages of development, in which we are there to guide you, innovate and accelerate your project.

1

Defining your project

for better co-development

The first step in our co-development process is to define your plastics processing project. Starting with a simple idea, we work closely with you to gather a complete brief. The latter includes: your needs, your targets, and essential input data for your project’s success. As facilitators, our role is to guide you in clarifying your ideas, structuring precise specifications, and setting concrete objectives.

At the same time, we make sure that all the data are compliant with the specific standards of your industry and market. The results of this first stage is a clear vision of your project, with well-defined expected values. These values guide every subsequent step in our process, guaranteeing that the final product will meet your expectations while respecting the standards and the required specifications.

2

Creativity and innovation, to make your product unique

Innovation and creativity are at the heart of our approach at Buathier. As a result, our team of plastic injection experts excels at stimulating creativity and generating innovative ideas. Our aim is to make your product not only unique, but also competitive in the market place.

Thanks to our vast experience, we offer creative and innovative concepts to optimize and and maximize the potential of your plastic injection moulded product. We firmly believe in optimizing your ideas, and we achieve this through a variety of cutting-edge plastic injection technologies, guaranteeing unique, high-performance products.

Futhermore, our economic approach is based on creating clever, cost-effective solutions for every project. That’s why every steps of our process is designed to get the most of your ressources et and budget.

Laurent Capelli, Sales Manager

3

Product design, to stand out in your market

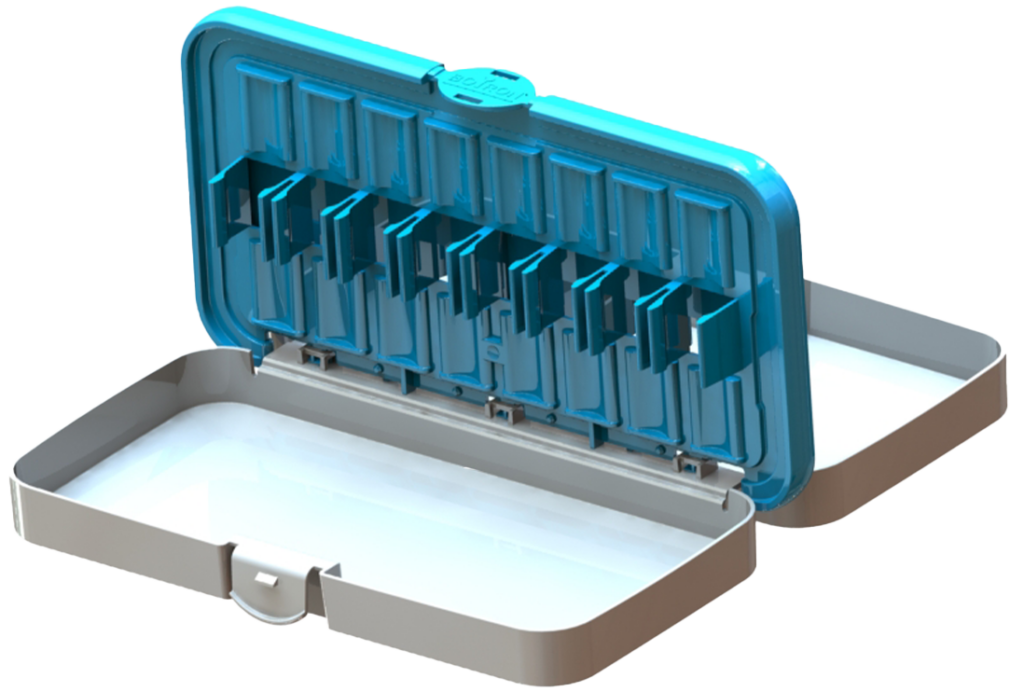

At Buathier, the product design phase is a ingenious, innovative, creative approach, where your vision begins to take shape. In fact, Buathier is committed to ensuring that every element of your product is carefully studied to define the characteristics that are essential to the creating value of your product. And it does so by meeting your specifications and the needs of your target market.

Thanks to our team of materials experts, together we choose the most suitable resins to guarantee durability, lightness, quality, and meet the necessary characteristics of your product.

3D design brings your vision to life, highlighting the advantages of plastic injection molding in terms of flexibility and complexity of form.

We are committed to minimizing our impact on the environment through life-cycle analysis (LCA) and the application of “Reduce, Reuse, Recycle” principles. We are providing 2D and 3D product files for your peace of mind and satisfaction. Finally, our formal or functional prototyping ensures that the product meets your requirements before going into series production.

Thanks to our team of materials experts, together we choose the most suitable resins to guarantee durability, lightness, quality, and meet the necessary characteristics of your product.

3D design brings your vision to life, highlighting the advantages of plastic injection molding in terms of flexibility and complexity of form.

We are committed to minimizing our impact on the environment through life-cycle analysis (LCA) and the application of “Reduce, Reuse, Recycle” principles. We are providing 2D and 3D product files for your peace of mind and satisfaction. Finally, our formal or functional prototyping ensures that the product meets your requirements before going into series production.

4

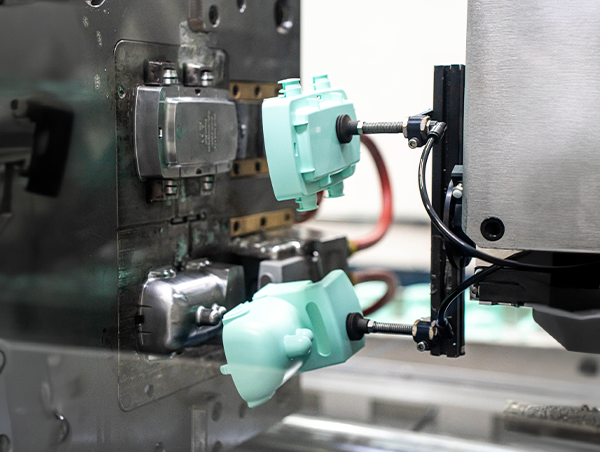

Industrializing your product

Industrialization is the key stage in taking your concept from design to reality. At the heart of this stage is the study, design and custom manufacture of injection molding tools, guaranteeing the repeatability and precision required for high-quality products. Once these tools are ready, we carry out an in-depth process qualification, where parameters are carefully optimized to meet your industry’s specific standards.

We also offer a wide range of assembly, decoration and finishing processes to customized your plastics products ensuring that they meet the highest quality standards. In addition, we take care of the packaging of your products, with tailor-made packaging options designed to meet your needs in terms of logistics, protection and presentation.

Before going into series production, we produce initial samples, giving you full validation and confidence that the final product will meet your expectations in terms of quality and functionality.

The industrialization is the final milestone on the to realizing your plastic vision, highlighting the advantages of our engineering expertise, manufacturing and customization to make your project a total success.

Our aim is to offer to you a product that is ready for mass production.