Buathier, is your factory !

Plastic parts and sub-assemblies

made in France

|

With over 60 years experience, BUATHIER is recognized for its expertise in the manufacture of colored, transparent and decorated plastic parts and sub-assemblies.

We have the ability to create parts with specific skills that go far beyond aesthetic. We meet the most stringent standards, with specific skills (waterproof, microwaveable, etc.), for the food, childcare, electrical and many other sectors.

For more than six decades BUATHIER has been committed to excellence and innovation to satisfy you. BUATHIER is equipped to handle your projects in plastic injection, with a fully robotized, high-speed machine park, for the manufacture of your plastic parts from medium to large production runs.

From the manufacture of your parts to the delivery of your products, we help you get the most out of your products in store, we support you in 4 stages.

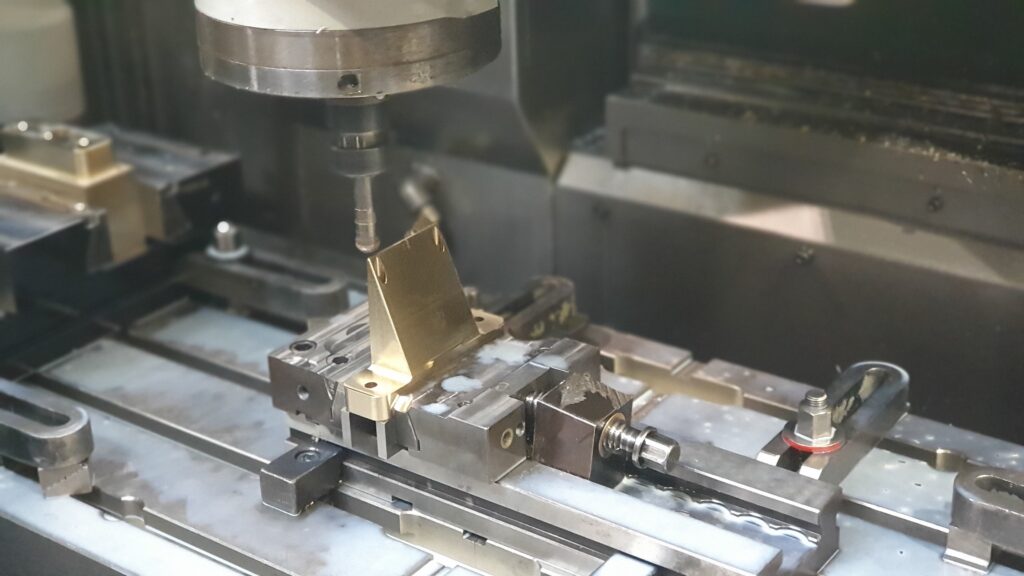

Tools design

At Buathier, we understand that the quality of an injected part depends largely on the quality of the plastic injection mold. That’s why we pay meticulous attention to the design and manufacture of our molds. Each mold is tailor-made, by complying with specifications and a 2D and 3D study.

Our developing team has exceptional know-how in designing the “safest and strongest” molds, guaranteeing the quality of the parts produced. For moldmaking, we collaborate with a network of local and international moldmaking partners with a proven track record over the years. This diversity enables us to offer flexible solutions, including low-cost molding options that can optimize your investment budget.

Our mold in production are treated with the utmost care and our mold maintenance team is at your disposal for all necessary interventions, such as changing versions, maintenance, modifications, etc.

After each production batch, every mold is meticulously cleaned, checked, protected, and stored in our dedicated mold storage warehouse.

We master the management and logistics of mold transfers. Once in our factory, we carry out an initial test on the press and, if necessary, recommend a list of possible improvements. This process of monitoring and improvement is the key to our commitment to quality and customer satisfaction.

Injection molding of your plastic parts and sub-assemblies

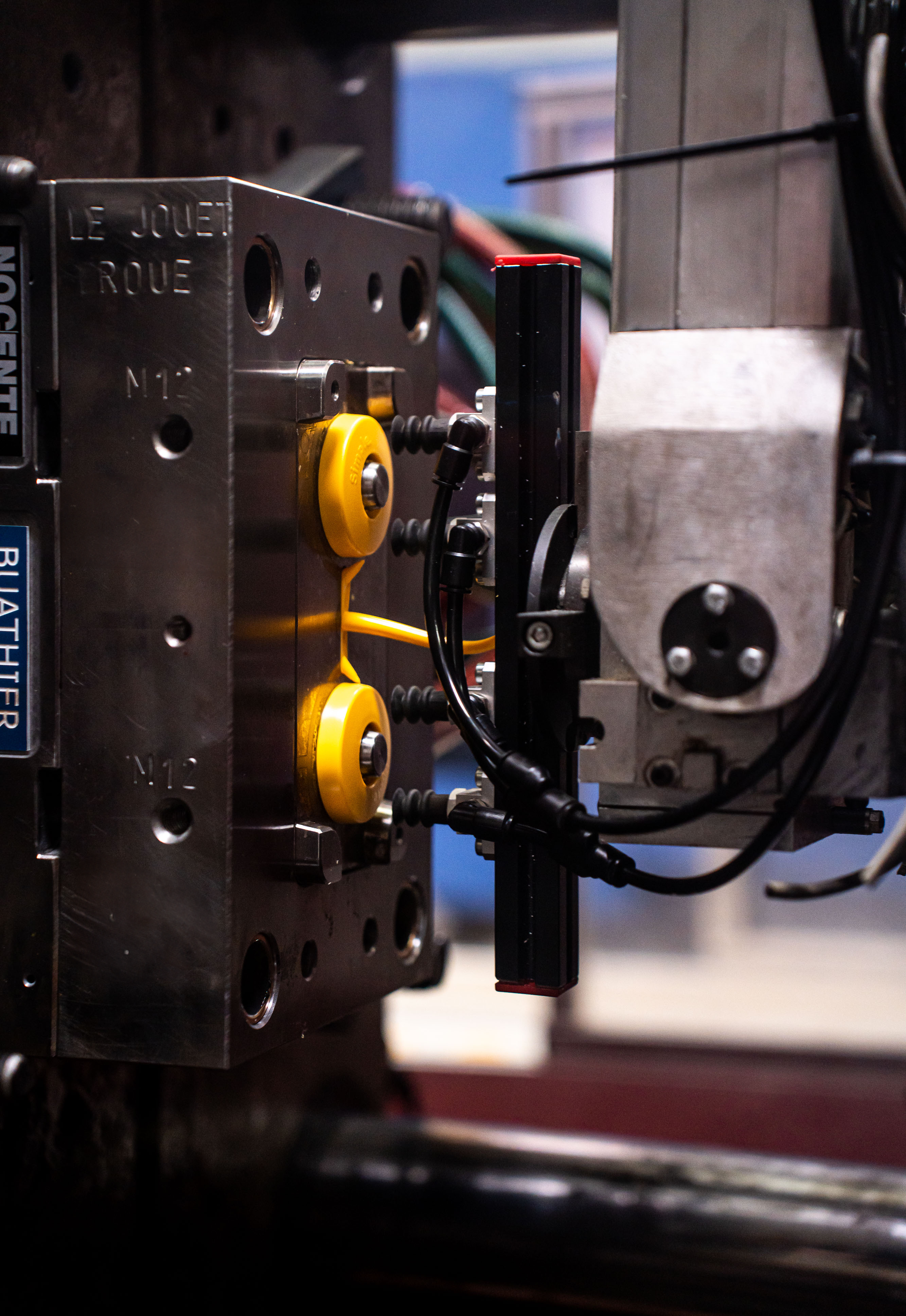

industrial site

At the heart of our factory, we have 20 injection molding machines, including 3 bi-material, all robotized. This state-of-the-art equipment enables us to push back the limits of creativity and technology to bring high-precision plastic parts to life.

In addition, BUATHIER works with a wide range of materials, including environmentally-friendly biopolymers, recycled polymers, standard, engineering and even high performance plastics. This versatility enables us to meet a multitude of customer requirements and specifications.

Our expertise encompasses a variety of advanced technologies, including bi-material injection and overmolding (plastic/metal), mono-material injection, injection with component overmolding, In Mold Labelling (IML) and In Mold Assembly (IMA). These technologies are mastered by our highly-qualified team to offer tailor-made solutions to our customers.

One of our added values is the mastery of technical features such as water-resistance, microwave resistance, durability in dishwasher cycles, dimensional accuracy, RFID chip integration and much more. This technics enables us to respond to majors challenges in art of dinning, childcare, food and many other markets.

Assembly & customization for creative, aesthetic products

In addition to manufacturing high-quality plastics parts , BUATHIER offer customization and assembly services to meet specifics needs. This stage of the manufacturing process is crucial to add value to products and meet the customization requirements.

Decoration and personalization techniques are varied and include In Mold Labelling (IML), pad printing, screen printing, 3D sublimation, hot stamping, laser marking and painting.

Packaged, shelf-ready products

We take care of the entire management of Gencodes and thanks to our proximity with our network of printers, we can also offer you customized packaging solutions tailored to your needs.

This guarantees that your products are ready to be dispatched to your various distribution networks, and ready to be distributed and put on the shelves.